EXCELLENCE IN ENGINEERING, QUALITY & SERVICE FOR PLASTIC PROCESSING EQUIPMENT

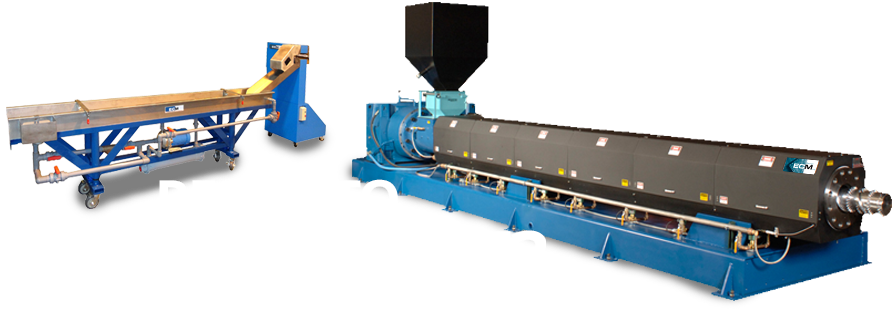

Extruders, compounders and recyclers throughout the world count on plastics processing equipment from Berlyn ECM. We're the first call for plastic processing equipment for 4 reasons:

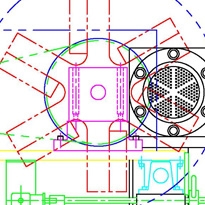

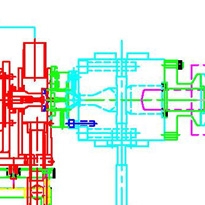

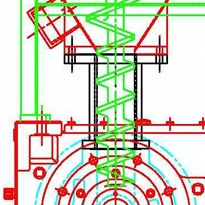

- Expert engineering capabilities for the highest quality equipment

- A one-stop-shop for complete plastics processing solutions

- Dedicated to providing outstanding customer service

- Over 60+ combined years of industry experience